DKOM - DIALOCK® 2-way diaphragm valve DN 15:65

DIALOCK® diaphragm valve with flanged monolithic body, drilled PN10/16. Face to face according to EN 558-1.

The DK DIALOCK® diaphragm valve is particularly suitable for shutting off and regulating abrasive or dirty fluids. The new internal geometry of the body increases flow coefficient, reduce pressure drop and allows a sensitive and precise adjustment along the entire stroke of the shutter. The DK is extremely compact and very light. The innovative handwheel is equipped with a patented immediate and ergonomic operating locking device that allows it to be adjusted and locked in any position.

Main features:

- High visibility graduated optical position indicator protected by a transparent cap with seal O-Ring

- Customisation plate: the customisation lets you identify the valve on the system according to specific needs

- DIALOCK® SYSTEM: innovative handwheel with a patented immediate and ergonomic operating locking device that allows it to be adjusted and locked in over 300 positions

- Handwheel and bonnet in high mechanical strength and chemically resistant PP-GR, providing full protection by isolating all internal metal parts from contact with external agents

- Floating pin connection between the control screw and diaphragm to prevent concentrated loads, improve the seal and extend its lifetime

- New design of valve body interior: substantially increased flow coefficient and reduced pressure drop. The degree of efficiency reached has also enabled the size and weight of the valve to be reduced

- Adjustment linearity: the internal profiles of the valve also greatly improve its characteristic curve, resulting in extremely sensitive and precise adjustment along the entire stroke of the shutter

- Valve anchoring bracket integrated in the body, with threaded metal inserts allowing simple panel or wall mounting using the PMDK mounting plate (supplied as an accessory)

EPDM

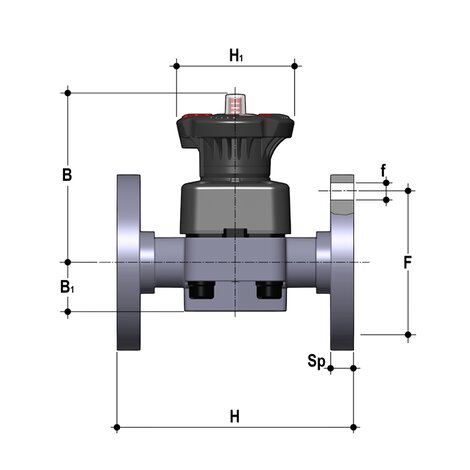

| Reference | d | DN | PN | B | B1 | F | f | H | H1 |

Sp | U | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DKOM020E | 20 | 15 | 10 | 102 | 25 | 65 | 14 | 130 | 80 | 13,5 | 4 | 817 |

| DKOM025E | 25 | 20 | 10 | 105 | 30 | 75 | 14 | 150 | 80 | 13,5 | 4 | 850 |

| DKOM032E | 32 | 25 | 10 | 114 | 33 | 85 | 14 | 160 | 80 | 13,5 | 4 | 892 |

| DKOM040E | 40 | 32 | 10 | 119 | 30 | 100 | 18 | 180 | 80 | 14 | 4 | 1005 |

| DKOM050E | 50 | 40 | 10 | 149 | 35 | 110 | 18 | 200 | 120 | 16 | 4 | 1771 |

| DKOM063E | 63 | 50 | 10 | 172 | 46 | 125 | 18 | 230 | 120 | 16 | 4 | 2453 |

| DKOM075E | 75 | 65 | 10 | 172 | 46 | 145 | 18 | 290 | 120 | 21 | 4 | 2997 |

FKM

| Reference | d | DN | PN | B | B1 | F | f | H | H1 |

Sp | U | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DKOM020F | 20 | 15 | 10 | 102 | 25 | 65 | 14 | 130 | 80 | 13,5 | 4 | 817 |

| DKOM025F | 25 | 20 | 10 | 105 | 30 | 75 | 14 | 150 | 80 | 13,5 | 4 | 850 |

| DKOM032F | 32 | 25 | 10 | 114 | 33 | 85 | 14 | 160 | 80 | 13,5 | 4 | 892 |

| DKOM040F | 40 | 32 | 10 | 119 | 30 | 100 | 18 | 180 | 80 | 14 | 4 | 1005 |

| DKOM050F | 50 | 40 | 10 | 149 | 35 | 110 | 18 | 200 | 120 | 16 | 4 | 1771 |

| DKOM063F | 63 | 50 | 10 | 172 | 46 | 125 | 18 | 230 | 120 | 16 | 4 | 2453 |

| DKOM075F | 75 | 65 | 10 | 172 | 46 | 145 | 18 | 290 | 120 | 21 | 4 | 2997 |

PTFE

| Reference | d | DN | PN | B | B1 | F | f | H | H1 |

Sp | U | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DKOM063P | 63 | 50 | 10 | 172 | 46 | 125 | 18 | 230 | 120 | 16 | 4 | 2453 |

| DKOM075P | 75 | 65 | 10 | 172 | 46 | 145 | 18 | 290 | 120 | 21 | 4 | 2997 |

| DKOM020P | 20 | 15 | 10 | 102 | 25 | 65 | 14 | 130 | 80 | 13,5 | 4 | 817 |

| DKOM025P | 25 | 20 | 10 | 105 | 30 | 75 | 14 | 150 | 80 | 13,5 | 4 | 850 |

| DKOM032P | 32 | 25 | 10 | 114 | 33 | 85 | 14 | 160 | 80 | 13,5 | 4 | 892 |

| DKOM040P | 40 | 32 | 10 | 119 | 30 | 100 | 18 | 180 | 80 | 14 | 4 | 1005 |

| DKOM050P | 50 | 40 | 10 | 149 | 35 | 110 | 18 | 200 | 120 | 16 | 4 | 1771 |

- Connection system for solvent weld, threaded and flanged joints

- Optimised fluid dynamic design: maximum output flow rate thanks to the optimised efficiency of the fluid dynamics that characterise the new internal geometry of the body

- Internal components in metal, totally isolated from the fluid and external environment

- Modularity of the range: only 2 handwheel and 4 diaphragm and bonnet sizes for 7 different valve sizes

- Non-rising handwheel that stays at the same height during rotation, equipped with a graduated optical indicator protected by a transparent PVC cap with seal O-Ring

- Bonnet fastening screws in stainless steel protected against the external environment by PE plugs. Absence of metal parts exposed to the external environment to prevent any risk of corrosion

- CDSA (Circular Diaphragm Sealing Angle) system that, thanks to the uniform distribution of shutter pressure on the diaphragm seal, offers the following advantages:

- reduction in the tightening torque of the screws fixing the actuator to the valve body

- reduced mechanical stress on all valve components (actuator, body and diaphragm)

- easy to clean valve interior

- low risk of the accumulation of deposits, contamination or damage to the diaphragm due to crystallisation

- operating torque reduction

Videos

DK DIALOCK DN 15-65 - manual and actuated version

get_app

get_app

get_app

get_app